PP melt blown nonwoven fabric production line is an equipment that used to produce pp melt blown fabric which are widely used both in face mask and medical industry. And the principle of this equipment is as below:

Auto Feeder feeds 100% new drawing class polypropylene into Extruder. Then pp materials are melt by heating through Extruder. Roots Blower blows the air into Air Heater and then the heated air will blow the liquid melted polypropylene materials through the Nozzle Heads (with hundreds of small holes in the mold), and finally threaded materials arrive at the Receiving car. Receiving car can be customized.

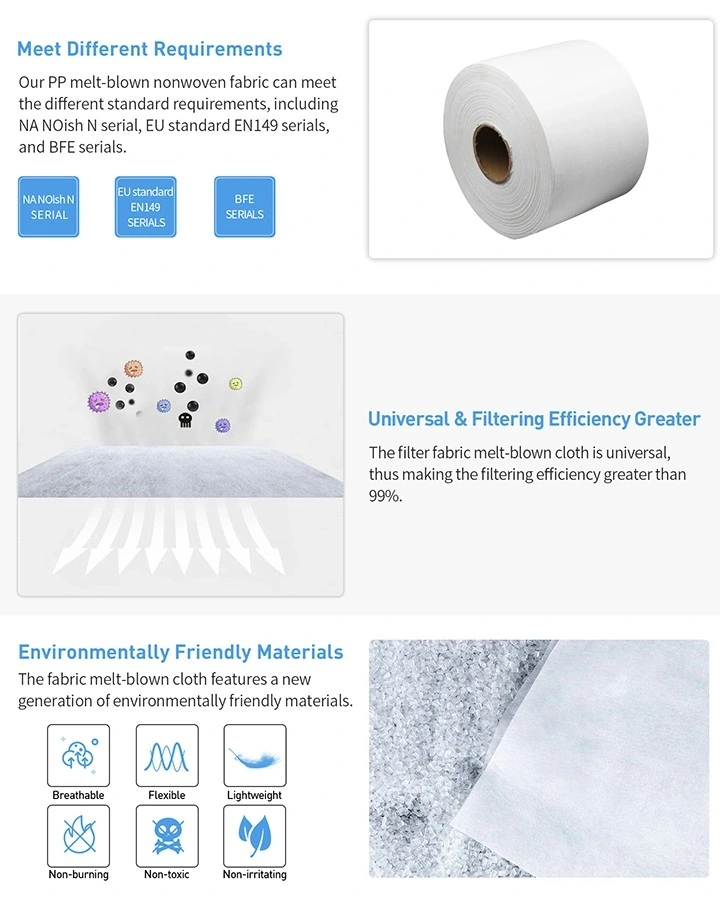

The micro-denier fiber (less than 0.1 denier per filament) is very fine, which only can be produced by melt blown process.It can not be used as nonwoven fibrous raw material alone but the appearance of nonwoven melt blown fabric solves this problem. Nonwoven melt blown fabric is anti-static, breathable, eco-friendly, soft, damp proof, recyclable, easy to shape, water and oil repellence, and antimicrobico.

Service

Training: 2 solutions

1. Welcome to stay in our factory for a long-term training 7~14days until you master all the skills.

2. We provide an installing and training service to your factory in 7~14days until you master all the skills and you should take care of the plane ticket, accommodation at buyer location

Warranty

Two-years warranty is ensured. We provide new parts (except easy-wear parts) for free if your machine is broken

After sale service

Engineers available to service machinery overseas.

RFQ1.Machine delivery time:

A:One weeks Quick shipping

2.Machine installation and training

A:Video support and manual book